| Sign In | Join Free | My xxjcy.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xxjcy.com |

|

Brand Name : ZHBREWING

Model Number : ZH-1500L

Certification : CE ISO

Place of Origin : China

MOQ : ≥1

Price : Negotiation

Payment Terms : L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability : 2 sets per month

Delivery Time : 35-45 working days

motor and voltage : according to your requirement

pressure : macnical pressure valve

After-sales Service Provided : Engineers available to service machinery overseas

material : SUS304 or red copper

Processing : Polishing and welding no dead corner

control system : PLC or DCS system

Product features:

1. Appearance clean and generous: The tank is polished by mirror, and the equipment is bright;

2. Good insulation effect: The equipment is divided into two kinds of heat insulation and cold insulation, which is the best to ensure the temperature of the beer brewing process;

3. Visualization operation: the equipment is controlled by PLC, and the fermentation tank is equipped with a glass tube level gauge, which is convenient for visual operation;

4. Low energy consumption: environmental protection, energy saving, low power consumption, saving energy consumption of about 20%

| 1 | malt milling system | malt miller machine grist case |

| 2 | Mash system | Mash tun/Brew kettle (Or mash tun/lauter and brew kettle whirlpool) |

| 3 | Fermenting system | Beer fermenters Bright beer tanks Yeast adding tank Accessories, such as sample valve, pressure gauge, safety valve and so on |

| 4 | Cooling system | Glycol tank Refrigerating unit Glycol pump |

| 5 | CIP cleaning system | disinfection tank & alkali tank &cleaning pump etc. |

| 6 | Controller | Control system, we have PLC automatic and semi-automatic, the elements brand include LG, Siemens and so on. |

| 7 | Kegging system | kegging system ( keg washer and keg filler machine), the control system brand is Siemens. |

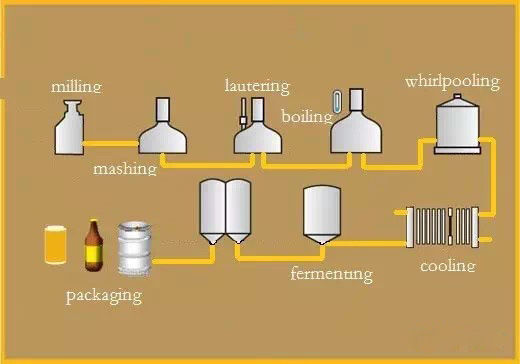

Simple model diagram

1. Malt mill system

Double roller

Controlling input adjustable slide gate,equip motor, pulley, belt etc;

Power: Adjustable.

2. Mash system:

1. System is mainly composed by mash tun, lauter tank, brew kettle, whirlpool tank, hops adding equipment etc.

2. The main body of mash tun, mash copper system all using international standards, high-quality 304 stainless steel.

3. The manufacture is using of modern automatic plasma & laser cutting and the protection of pure argon gas welding and other technology.

4. The full mirror polished technology for the inside of the tanks which expose to materials such as wheat mash; external matte polished to ensure customers with high quality and low price, beautiful mash system.

Technical Parameters

1. Manhole, stainless steel top manhole or glass sight manhole

2. Temperature measurement method: PT100 temperature probe.

3. Cleaning method: Fixed rotate cleaning ball and sprage coil on top.

4. Mechinical agitation& Raker: at the top stirring. High power, low speed to ensure complete worse layer.

5. Milled sieve plate,0.7mm distance with discharge hole.

6. Whirlpool tangent pumped at 1/3 height of the tank and glass level.

7. Stainless steel legs, with screw assembly to adjust leg height.

Glass manhole

Stainless steel manhole

Hops filter

3. Fermentation system

Fermentation tank

Technical Parameters

1. Thermal insulation material: Polyurethane (PU) foam, Insulation thickness: 75-100MM.

2. Manhole: Side manhole or top manhole

3. Design pressure 3bar, Working pressure: 15bar;

4. Bottom design: 60degree cone for easy to exist yeast.

5. Cooling method: Dimple cooling jacket

6. With: CIP arm with spray ball, pressure gauge, Mechanical pressure regulating valve, CO2 adding device, sampling valve, breath valve, Ice water solenoid valve, thermometer, etc.

7. Surface protection, weld slinging band with stainless steel leg, adjustable bolt to adjust leg height;

8. Argon arc welding, Inside and outside the polishing, No welding corner to ensure the quality of the fluid

4. Cooling system

Mainly include glycol tank, cold water tank and chiller unit.

Our chiller use environmentally friendly refrigerants.

5. CIP Cleaning system

Our advantage:

Half open manhole for easy cleaning and no dead corner.

6. Control system

Two choose

1. Manual control 2. PLC control

Difference: PLC control have a touch screen.

Shandong Zunhuang Brewing Equipment Co., Ltd is the domestic integrated industrial and tradecomprehensive enterprise dedicated in research, manufacturer, development, sales and after-sale service, until now have the 16 years produce experience, company focuses on beer system project that refer to fruit wine equipment, white spirit and alcohol equipment etc, corollary equipment, our company purpose: “Quality first, customer highest”, use the short period provide direct and comprehensive service, and improve the products’ valve and market competitive.

FAQ:

1.Q: Are you a manufacturer?

A: We are the manufacturer of beer brewing equipment for 16 years.

2.Q: Can I have the customized products for myself?

A: Yes,we can design and manufacture as client's requirements.

3.Q: Can you guarantee your quality?

A: All of our products is applied with CE certificate and highly in accordance with GMP. Equipment is made of high quality of SUS304/316. Inspect certificate is available.

4.Q: How about the after sales service?

A: For our after-sale service, we promise all life of technical support to new and old customers.

All of our products is available with 10 years warranty even for spare parts within quality warranty period, our service is free of charge.

|

|

PLC / DCS Stainless Steel Beer Brewing System , 1500L Industrial Beer Brewing Equipment Images |